Incab Video Tour

MoreBlowing

Applied in tubes, ducts, trays, blocks, tunnels, collecting channels, with no risk of rodent attacks. Also applied for aerial installation between supports and buildings on external strength members or using the winding method.

Ducting

Applied in ducts, trays, blocks, tunnels, collecting channels, with a risk of rodent attacks.

Direct Buried

Applied in harsh environments with potential mechanical impact: in all ground types, swamps and harsh rivers.

Submarine

Applied in sea areas (coastal shelf and deep-sea), on navigable rivers, in lakes and water storage basins, in harsh environments, in bogs and unnavigable rivers.

Figure 8

Applied for aerial installations: on power lines, lamp posts, between buildings and constructions. Suitable for aerial installation on transmission equipment and power facilities in dielectric package.

Aerial

Applied for aerial installation on distribution and high voltage power lines, as well as railway catenary.

Indoor

Applied inside buildings (including vertical runs), in trays, channels, on outer sides of buildings, as well as in duct, in tubes and blocks. Suitable for blowing-in into protecting polyethylene tubes.

Drop

Applied for aerial installation on transmission towers, lamp posts, between buildings and constructions.

OPGW/Ground Wire

Applied in the construction of fiber-optic link on overhead transmission lines of 35 kV and more.

Fire Rated

Used for stationary installation when the optical fiber needs extra protection from mechanical damages.

Specialty Cable

For fiber optic monitoring systems.

Materials

Incab Video Tour

MoreWhen presenting Incab we always speak about our

"triple I": I³ = I × I × I : innovative, intellectual,

individual.

We choose the most innovative technologies from among all available worldwide and build our products around them.

It is vital to us that our products always contain our maximum intellectual potential.

It is essential to us to address even the smallest details when serving our customers, no matter how large we grow.

We would be very happy to prove our "triple I" to you!

Optical cable for all applications

20 721 900

kilometers of fiber processed

914 300

kilometers of cable produced

866 030

kilometers of fiber processed

80 600

kilometers of cable produced

Number 1 plant in Russia and CIS in terms of production volume of fiber optic cable (in 2013–2015 and 2017-2025) and the volume of processed optical fiber (in 2012–2025) (according to the Association of Electrical Cable Manufacturers)

— Quality Management System is certified to ISO 9001:2015 by TÜV Thüringen.

— Environmental Management System and Health and Safety Management System are certified

to ISO 14001:2015 and ISO 45001:2018 by TÜV Thüringen.

— All materials used in cables manufacturing are RoHS compliant.

cable produced in 2025

Enhanced Corning® SMF-28® Ultra fiber

low, medium and high density polyethylene Borealis

The most exciting events

in the plant and around.

If you

don't want to miss

the most important news,

subscribe to our newsletter.

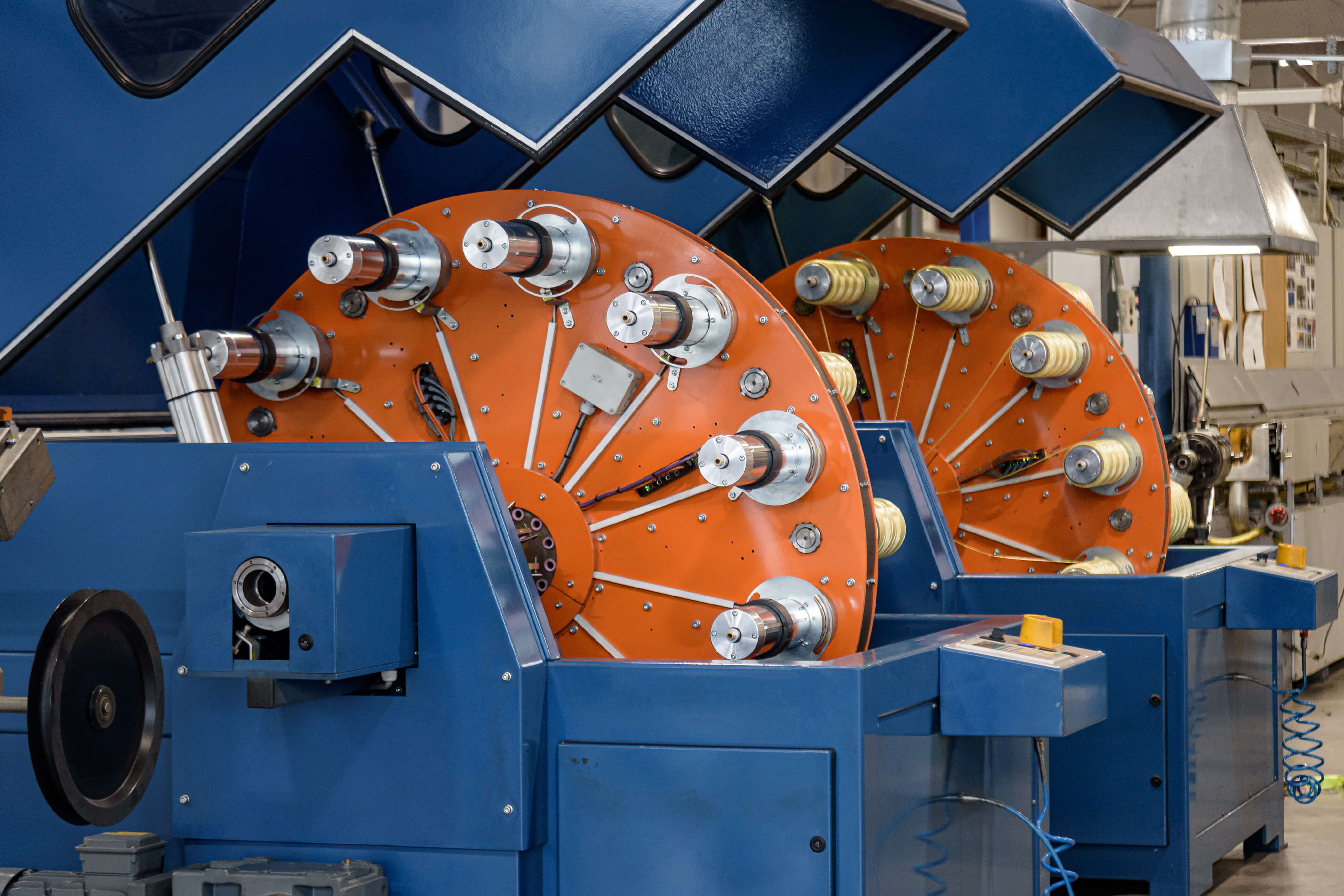

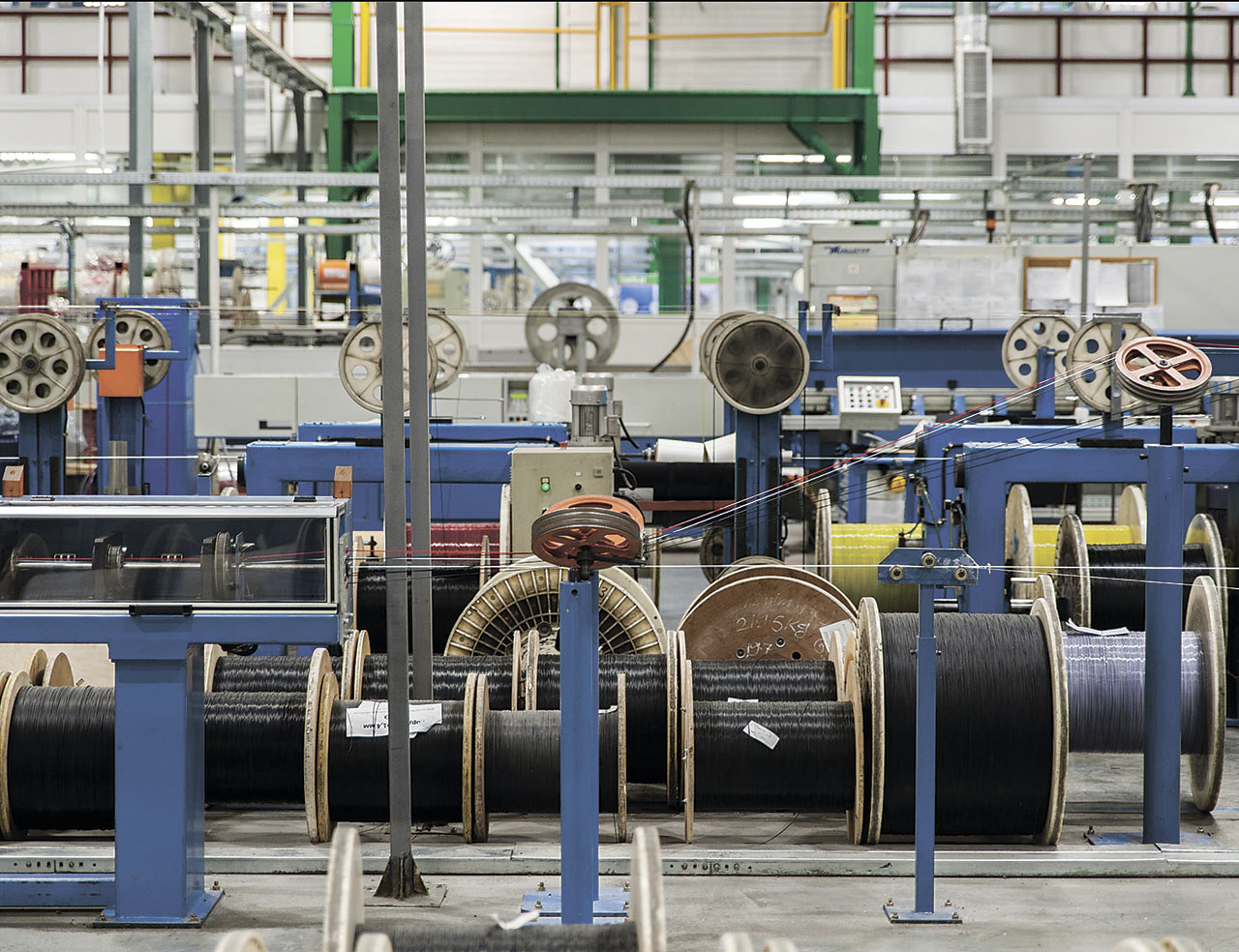

Production capacity: 8000 km of cable per month

Over 30 advanced manufacturing lines

from leading European producers

(Maillefer, Caballe, Mario Frigerio, Medek&Schorner,

Nexans, Photonium, Compotec and others)